This machine can make gowns and clothes fold and pack it use plastic bag . It has the advantages of good quality, low price, high output, saving labor and reducing cost. It can be customized according to customer’s requirements.

This machine is automatic, the whole process of automatic operation, computer infinite speed regulation operation is more flexible, the whole process of operation only needs one person.

Applicable clothing: protective clothing, dust-free clothing, surgical gown (length must be within the

range of machine parameters) and similar clothing, as shown in the following figure:

Applicable plastic bags: PP, PE, OPP self-adhesive envelope plastic bags.

Applicable plastic bags: PP, PE, OPP self-adhesive envelope plastic bags.

※Note: Considering the diversity of clothing materials and shapes, the actual test shall prevail.

Corresponding to some clothes with long hair, many thin ribbons, etc., cannot be used in this program.

feeding belt is completed)

garment left-right to be folded. (The scrubbing mechanism is completed)

will be pre-pressed before bagging)

The pre-compression mechanism is completed).

bagging mechanism)

is completed)

Applicable plastic bags: PP, PE, OPP self-adhesive envelope plastic bags.

| NO | Material | Min width of clothes before folding | Min length of clothes before folding | Min width after folding | Min length after folding | Min thickness after folding |

| 1. | Clothes | 400-800mm | 450-1500mm | 260-400mm | 200-420mm | 5-100mm |

| 2. | Plastic bag | Min size of plastic bag :280*280mm | Max size of plastic bag :450*420mm |

| Clothes Feeding | 1set |

| Folding unit | 1set |

| bagging unit | 1set |

| Sealing and Cutting unit | 1set |

Ⅳ.Configuration List:

| Feeding device | Origin :China Quantity :1 Note : |

|

| Stepper motor | Origin :China Quantity :10 Note : |

|

| cylinder | Origin :China Quantity :22 Note : |

|

| Cutting device | Origin :China Quantity :1 Note : |

|

| Photoelectric sensor | Origin :China Quantity :5 Note : |

|

| electrical equipment | Origin :china Quantity : Note : |

|

| PLC | Origin :China Quantity :1 Note : |

Spare parts:

| No. | Product name | Quantity | Photo |

| 1 | sponge | 1pcs | |

| 2 | Monkey wrench | 1pcs | |

| 3 | Oil dropper | 1pcs | |

| 4 | Allen wrench | 1pcs | |

| 5 | Screwdriver | 1pcs | |

| 6 | Open spanner | 1pcs |

|

Machine type |

DH-B |

|

Production Speed |

400-550PCS/hour |

|

Voltage |

220V/380 50Hz |

|

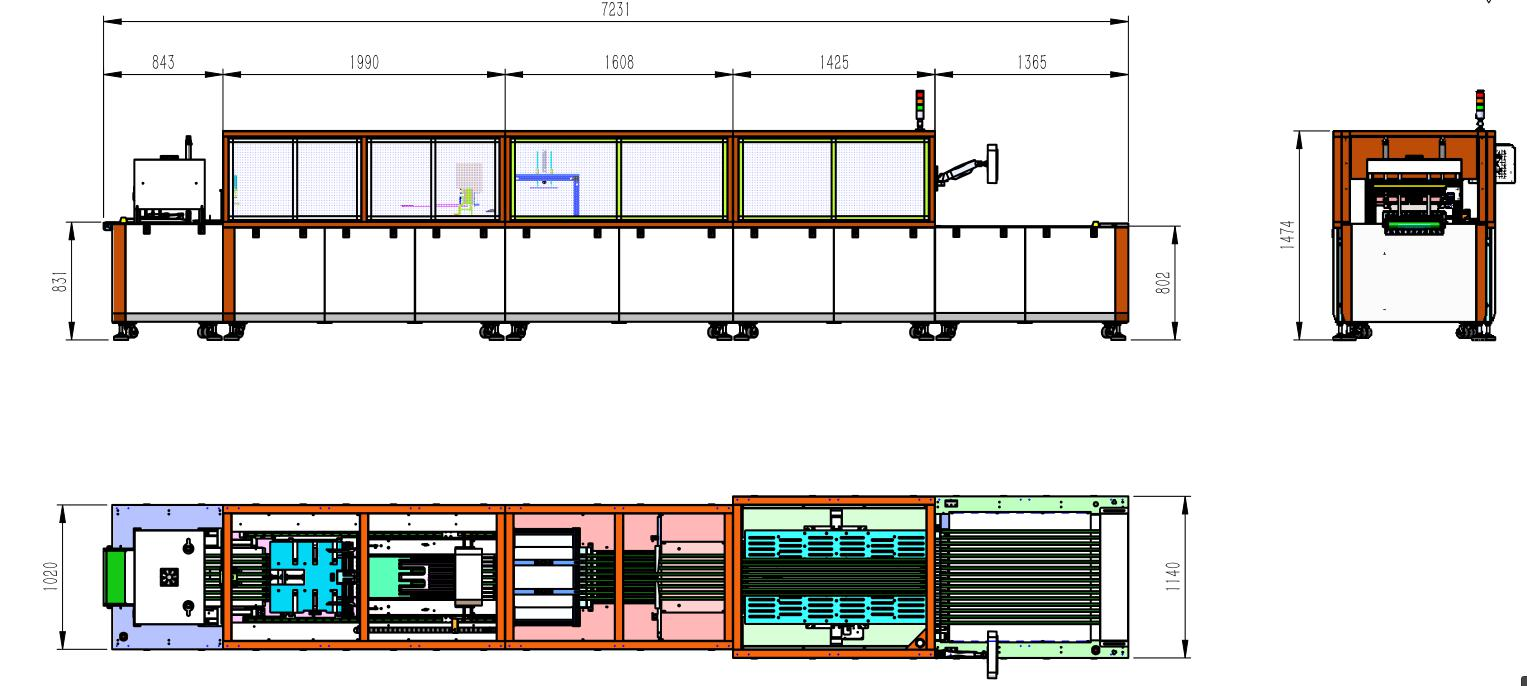

Overall size |

7231*1140*1450MM(L*W*H) |

|

Power |

5KW |

|

Machine weight |

2000KGS |