The Nonwoven Boot Cover Making Machine is designed for the high-speed production of disposable long-leg boot covers and short shoe covers. It supports nonwoven PP, SMS, laminated, and PE-coated materials, making it suitable for medical, cleanroom, pharmaceutical, food processing, and industrial protective applications.

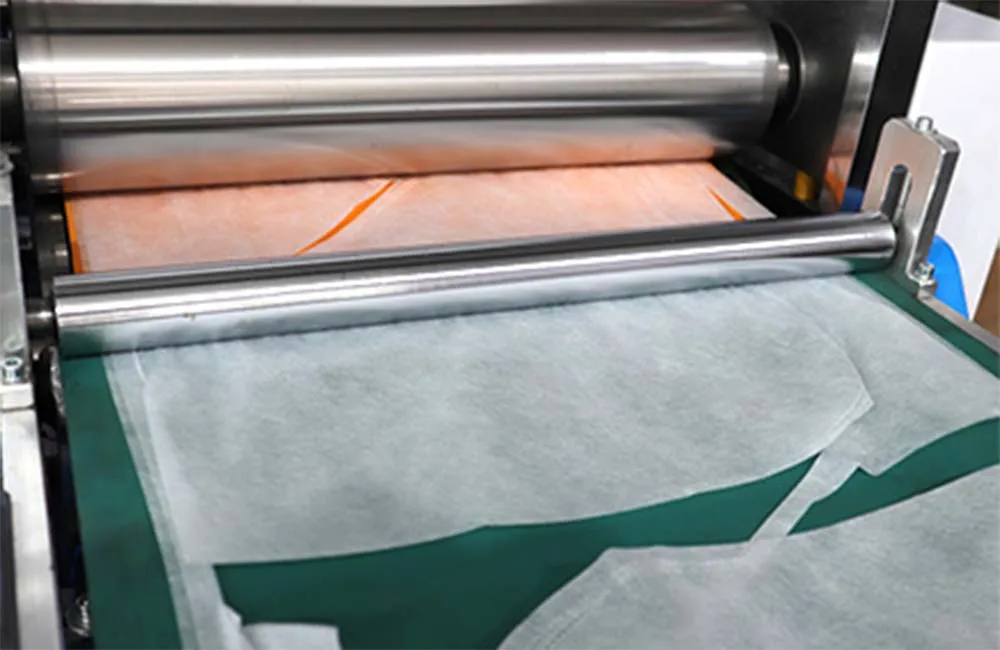

This machine can produce boot covers with or without ties, and can customize leg length, foot size, elastic position, and tie placement according to your market needs. With automatic feeding, ultrasonic welding, elastic insertion, cutting, and optional tie welding, it ensures stable product quality and consistent output.

Ideal for factories producing personal protective equipment (PPE), hospital supplies, and industrial protective clothing.

✔ Suitable for PP nonwoven, SMS, PE-coated nonwoven

✔ Short shoe cover & long boot cover production

✔ With or without tie design (elastic top / tie strap closing)

✔ Ultrasonic sealing for strong, clean welds

✔ Automatic feeding, elastic insertion, welding, and cutting

✔ Length, width & elastic tension fully adjustable

✔ Stable 24/7 continuous operation

✔ One operator only

| Item | Specification |

|---|---|

| Material | PP Nonwoven, SMS, PE-coated nonwoven |

| Product Type | Boot cover (long-leg) / Shoe cover (short) |

| Leg Length | 350–600 mm (customized) |

| Foot Size | 150–400 mm (customized) |

| Production Speed | 20–40 pcs/min (long type) |

| Elastic Type | Top elastic / ankle elastic / full surrounding elastic |

| Tie Design | Optional tie strap welding |

| Welding Method | Ultrasonic sealing |

| Power Supply | 220V/380V |

| Air Requirement | 0.5–0.8 MPa |

| Ultrasonic Sets | 2–6 sets |

| Operator | 1 person |

| Machine Dimension | Based on configuration |

Disposable boot covers are used in:

Hospitals & clinics

Cleanrooms

Pharmaceutical plants

Food processing factories

Chemical workshops

Labor protection industries

Laboratories & research facilities

Yes. Most models use 2–6 ultrasonic units depending on the sealing structure. More sonics = stronger welding.

You get:

1-year warranty

Online support within 7 hours

Detailed operation video

Spare parts package

Onsite installation & training (optional)