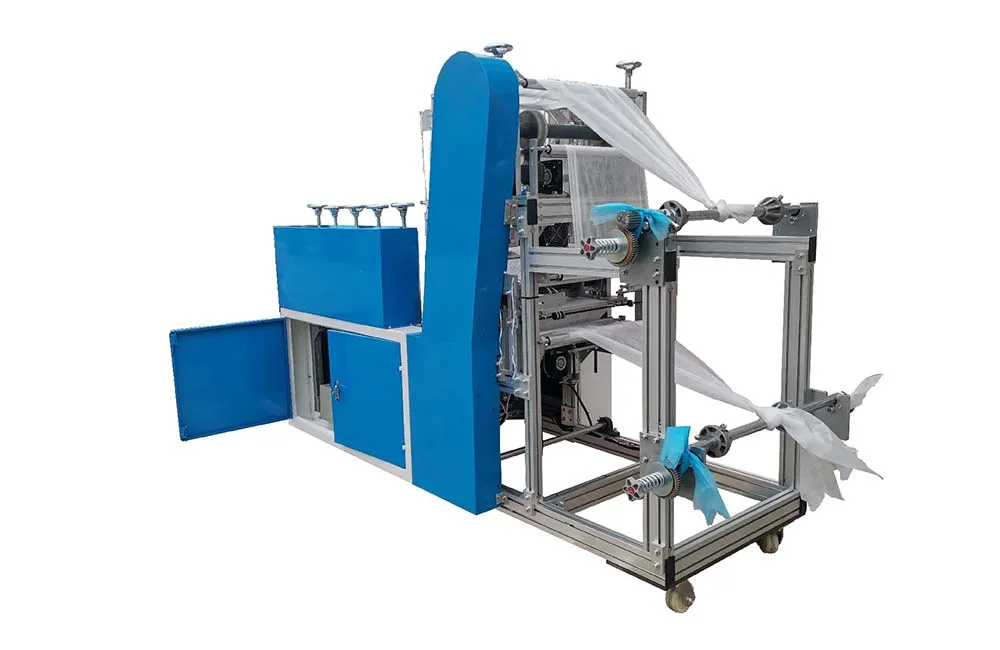

The Non Woven Sleeve Making Machine is a fully automatic production line designed for manufacturing disposable arm sleeves used in hospitals, laboratories, cleanrooms, food-processing facilities, beauty salons, industrial factories, and protective environments.

Using non-woven fabric (PP / SMS) as the main material, the machine completes feeding → forming → ultrasonic sealing → elastic welding → cutting → finished sleeve output in one continuous, automated process.

This machine is known for its strong ultrasonic welding, stable performance, consistent elastic tightness, and ability to produce various sleeve lengths and diameters by changing molds. It is ideal for PPE factories looking for high-speed and reliable production.

Fully Automatic Production

From feeding to sealing and cutting, only 1 operator is required.

High Production Speed

Standard speed: 100–150 pcs/min, depending on material and sleeve size.

Ultrasonic Welding System

Clean, firm, and hygienic seams without glue. Suitable for medical-grade products.

Elastic Automatic Feeding

Automatic cutting and welding of elastic ensures consistent tightness on both ends.

Supports Multiple Materials

PP non-woven

SMS / SMMS

Laminated non-woven

Custom Size Options

Length, width, thickness, and elastic tightness can be customized based on customer samples.

PLC Touch Screen Control

Easy operation, temperature control, auto alarm, and auto-stop functions enhance reliability and safety.

Durable Machine Frame

Aluminum alloy structure, rust-free, stable performance suitable for long-term continuous running.

| Item | Specification |

|---|---|

| Machine Model | DH-SWM (Non Woven Sleeve Making Machine) |

| Material | PP Non-woven, SMS, SMMS, Laminated Non-woven |

| Material Thickness | 20–50 GSM (non-woven) / 0.02–0.06 mm (PE/CPE) |

| Production Speed | 100–180 pcs/min (adjustable) |

| Finished Sleeve Length | 300–450 mm (customizable) |

| Finished Sleeve Diameter | 150–250 mm (customizable) |

| Elastic Type | Double-end elastic, automatic cutting & welding |

| Sealing Method | Ultrasonic welding (non-woven) / heat sealing (PE film) |

| Power Supply | 220V / 380V, 50/60Hz (customizable) |

| Total Power | 4–6 kW (depending on configuration) |

| Air Pressure Requirement | 0.4–0.6 MPa |

| Machine Dimensions | ≈ 2700 × 1100 × 1500 mm |

| Machine Weight | ≈ 600–800 kg |

| Operation Staff Required | 1 person |

| Mold Change Availability | Yes — custom sizes available |

| Application Industries | Medical, Food Processing, Cleanrooms, Labs, Factories, Beauty Industry |

Yes. We can customize length, diameter, and elastic tightness according to your sample or market requirement.

Yes. It uses PLC + touch screen control, with automatic alarm and stop functions.

ONE year. and life long service.

Yes. We provide video guidance, online support, and engineer overseas installation if required.