Stable Finished Gown Output • Lower Labor • Export-Ready Consistency

Upgrade your PPE factory from manual sewing to repeatable, high-output gown production.

Basic information of cutomer and requirement

| Item | Details |

|---|---|

| Industry | Medical PPE Manufacturing (Disposable Gowns & Drapes) |

| Location | Spain |

| Products | Surgical Gowns / Isolation Gowns / Reinforced Gowns |

| Before | Manual sewing + small semi-automatic machines |

| Main challenges | Low output, unstable ultrasonic welding, high labor dependency, inconsistent size & quality |

| Upgrade reason | Stable quality for export + lower labor cost + reduced defect rate |

Problem → Solution → Result

| Stage | Description |

|---|---|

| Problem |

• Labour-intensive sewing and manual processing • Difficult to maintain consistent gown dimensions • Low daily output (1,500–1,800 pieces/day) • Frequent rework due to size deviation and weak welding • Customer lacked in-house technicians to maintain machine stability |

| Solution |

• Installed Deheng Automatic Surgical Gown Body Machine • Added automatic sleeve making machine for higher efficiency • Upgraded ultrasonic welding pressure settings and alignment • Integrated hard-treatment die-cutting roller for long lifespan • Enabled remote PLC support for fast debugging & adjustments • Optimized feeding tension to stabilize fabric size and welding strength |

| Result |

• Output increased to 12,200-13,000 gowns/day(finished gown) • Labour reduced from 16 operators → 3 operators (gown body and sleeve) • Defect rate reduced by ~12% • Size switching time reduced to under 10 minutes • Machine achieved 24/7 stable continuous running • Quality consistency improved & passed export inspection easily |

Whether you need a custom gown design or a budget for a new machine, we’re ready to assist, please feel free to email us at dehengmachinery@gmail.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

What is surgical gown making machine

Automatic Surgical Gown Making Machine (Non-woven Fabric) — produces disposable surgical/medical gowns from roll material through feeding, welding (ultrasonic), cutting and tying with PLC control. Adjustable gown size, 20–25 pcs/min output, suitable for SMS/PP materials.

Working Process

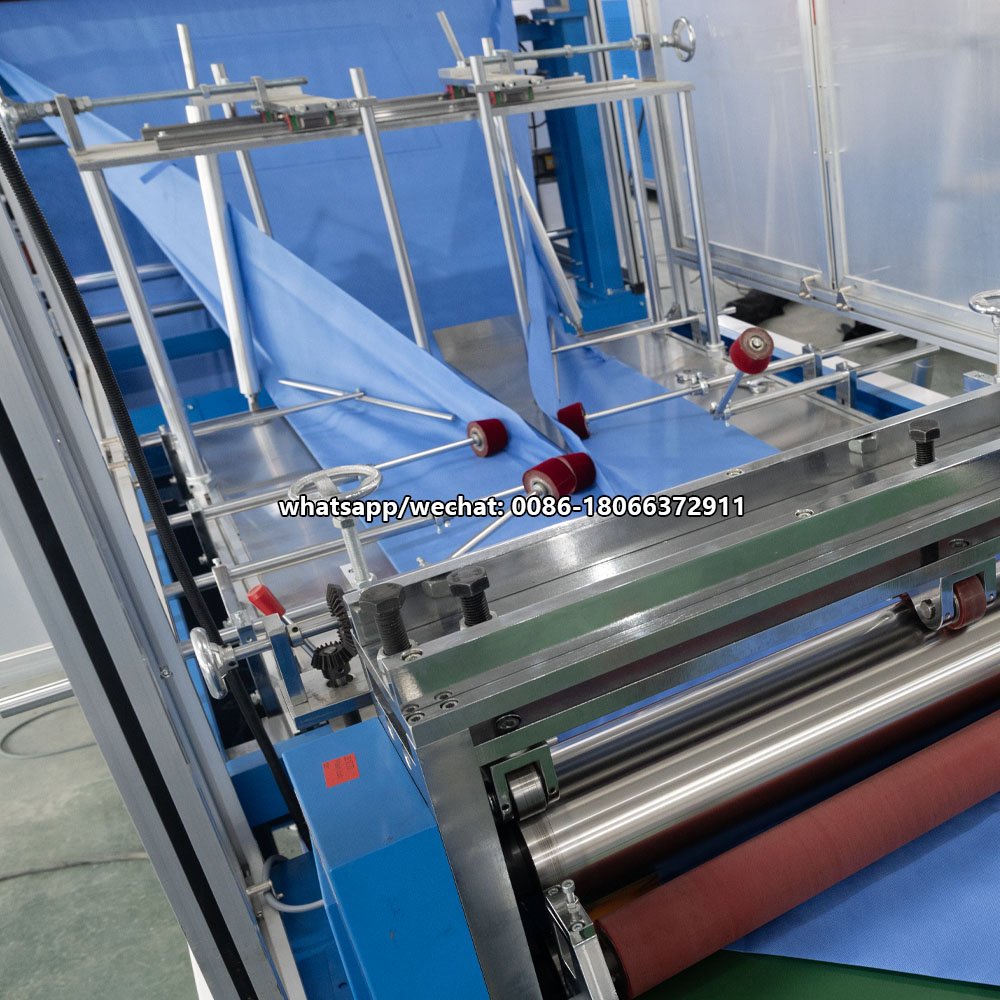

The full disposable surgical gown is made in three steps:

Gown Body Making Machine – forms the main gown body from non-woven roll material through ultrasonic cutting and welding.

Sleeve Making Machine – produces the gown sleeves automatically with ultrasonic sealing.

Sewing / Sealing Machine – joins the sleeves to the gown body and adds cotton cuffs if required.

This system creates complete SMS/PP surgical gowns with stable quality and high efficiency.

| Step | Description |

|---|---|

| 1. Raw Material Feeding | Automatic unwinding and feeding of SMS/SMMS non-woven fabric with stable tension control. |

| 2. Reinforcement Patch Feeding | Optional reinforcement patch material is fed and positioned according to gown design. |

| 3. Band Seal with Ultrasonic | Ultrasonic welding seals the reinforcement patch and secures all folded layers into the gown structure. |

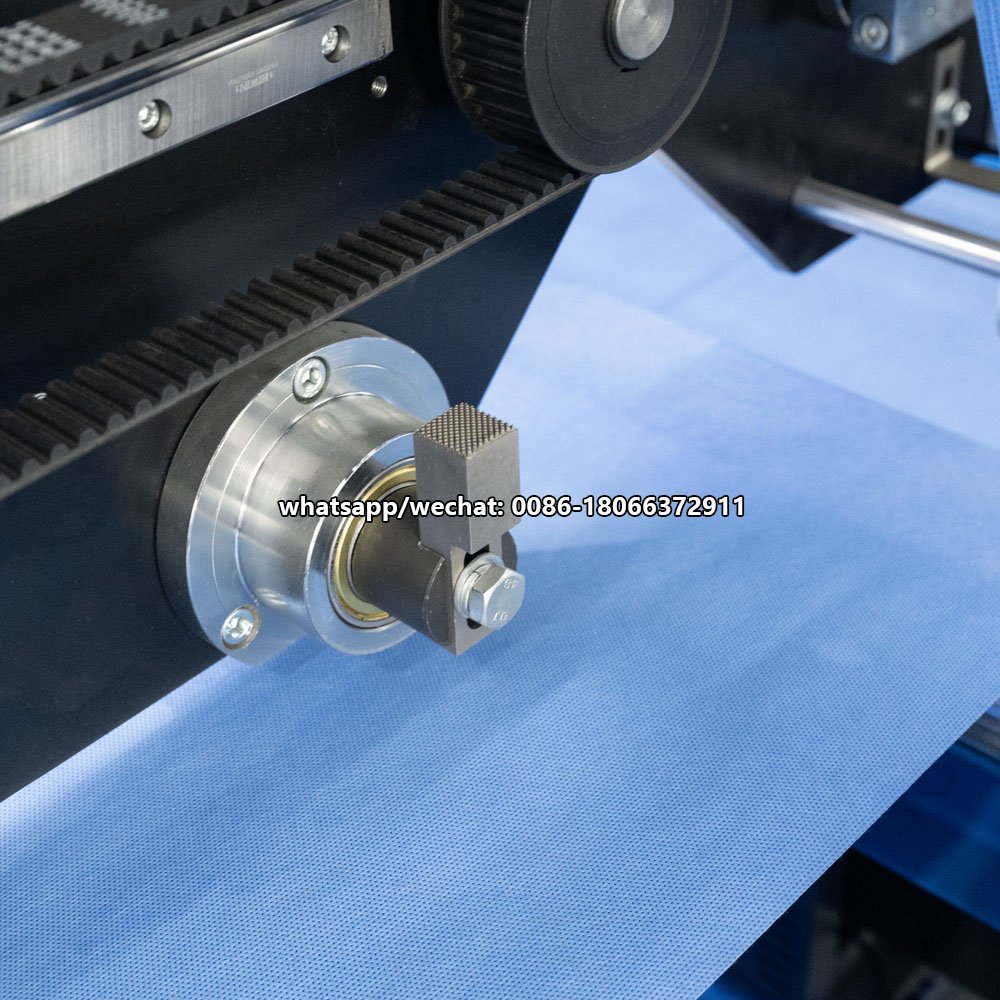

| 4. Die Cutting | Precision die-cutting system cuts the gown outline, sleeves area opening, and side contours. |

| 5. Folding | Automatic folding system prepares the gown body into the correct shape for the next stations. |

| 6. Neck Die Cutting | Dedicated cutting unit forms the neck opening with accurate and consistent dimensions. |

| 7. Gown Body Collection | Finished gown bodies are automatically stacked, ready for sleeve attachment or final assembly. |

| Step | Description |

|---|---|

| 1. Non-Woven Feeding | SMS / SMMS non-woven fabric is automatically unwound and fed smoothly into the machine with tension control. |

| 2. Elastic Feeding & Sealing | Elastic is fed, stretched, and ultrasonically sealed to form the wrist cuff (open or closed cuff depending on gown type). |

| 3. Reinforcement Patch Feeding & Attachment (Optional) | Optional reinforcement patch for the forearm area is automatically positioned and welded onto the sleeve material. |

| 4. Die Cutting | Precision die-cutting shapes the sleeve into its final contour, ready for the sleeve-to-body sewing or ultrasonic assembly. |

| Step | Description |

|---|---|

| 1. Sew Sleeve to Gown Body | The operator aligns the finished sleeves with the gown body and stitches them together along the armhole area to complete the gown structure. |

| 2. Stitch Cotton Cuff (If Required) | For surgical gowns with knitted cuffs, the cotton cuff is attached and stitched securely to the sleeve opening for a comfortable and tight wrist seal. |

Application

All Surgical Gown Types This Machine Can Produce

By Material Type

SMS Surgical Gown

SMMS Surgical Gown

Spunbond + Meltblown + Spunbond Composite

Laminated PE Reinforced Surgical Gown

Breathable Film Reinforced Gown

By Tie/Closure Type

Waist Tie Surgical Gown

Velcro Neck Closure Gown

Tie-on Neck Closure Gown

One-person (Card) Donning Gown

Two-person Tie Gown

By Sleeve Style

Set-in Sleeve Surgical Gown (most common)

Raglan Sleeve Surgical Gown

Kimono Sleeve Surgical Gown

Elastic Sleeve Cuff Gown

Cotton Knitted Cuff Surgical Gown

By Construction Style

Standard Surgical Gown

Reinforced Surgical Gown

Fully Reinforced Surgical Gown

Critical Zone Reinforced Gown (Chest + Sleeves Reinforcement)

Isolation Gown (Upgraded Reinforced Type)

By Protection Level (AAMI / EN13795)

AAMI Level 1 Gown (basic protection)

AAMI Level 2 Gown (low fluid protection)

AAMI Level 3 Gown (moderate fluid protection)

AAMI Level 4 Gown (high-risk, critical zones reinforced)

EN13795 Standard Performance Gown

EN13795 High Performance Gown

Optional Features Your Line Can Support

Ultrasonic-sealed seams

- 2/4/6 band seal gown

Reinforcement patch welding (chest/sleeve)

ultrasonic cuff sealing

Customization for size (S–XXL)

Main Configuration

| Item | Specification |

|---|---|

| Machine Type | Fully Automatic Surgical Gown Making Machine |

| Production Speed | 20–25 pcs/min |

| Applicable Material | SMS / SMMS / Spunbond / Reinforced PE Film (optional) |

| Gown Types | Standard Surgical Gown, Reinforced Surgical Gown |

| Sizes Supported | S / M / L / XL (adjustable) |

| Ultrasonic System | High-frequency ultrasonic sealing, automatic frequency tracking |

| Cutting Method | Precision rotary blade + ultrasonic cutting |

| Control System | PLC + Touch Screen (English interface) |

| Power Supply | 380V, 50/60Hz (customizable) |

| Air Pressure | 0.6–0.8 MPa |

| Installed Power | 12–18 kW (varies by model) |

| Machine Dimensions | Approx. 8–12 m (L) × 3–4 m (W) |

| Operation Required | 1–2 operators |

| Changeover Time | 10–20 minutes for size change |

| Features | reinforcement patch attachment, waist belt attaching, folding, shaping and customization |

| Maintenance | Easy-clean ultrasonic system, quick blade replacement, simple alignment |

| After-Sales Service | Remote support, spare parts, installation guidance |

Main Feature

PLC Intelligent Control System

The machine uses a stable and precise PLC controller to manage every step, including feeding, ultrasonic welding, shaping, cutting, and stacking. Operators can easily adjust parameters, improving accuracy and minimizing manual intervention.

Customized & Flexible Gown Production

This model focuses on maximum flexibility. It allows fast changeovers for different gown sizes, reinforcement patch styles, and production layouts. Since sleeves are added by an external sleeve machine, customers can freely choose their own sleeve style (set-in sleeve, raglan sleeve, knitted cuff, etc.) with no limitation.

Non-Stop Continuous Running

Built for long-term operation, the machine delivers stable and continuous output. Optimized feeding structure, servo-driven tension control, and durable ultrasonic components ensure smooth, non-stop running even at high speed.

Remote Monitoring & Service System

Through our online remote controller system, technicians can access machine parameters, diagnose alarms, update software, and provide real-time support — greatly reducing downtime and improving overall productivity.

Economic & Easy-Upgrade Modular Design

Because the sleeve unit is separated, customers enjoy a more economical investment while staying flexible:

Add any external sleeve machine

Choose any sewing style

Upgrade functions step by step

Replace worn parts at lower cost

This modular structure gives factories more control and helps reduce both maintenance and production costs.

Advanced Automation Solutions for Surgical Gown Manufacturing

Advantages of the automatic machine

| Item | Manual Sewing (Traditional) | Automatic Surgical Gown Making Machine |

|---|---|---|

| Production Speed | Slow, depends on worker skill and energy | High and stable, continuous production |

| Labor Requirement | Many workers needed for cutting, sewing, trimming | 1–2 operators can manage the whole line |

| Size Consistency | Size varies, relies on experience and hand measurement | Fixed by settings, size deviation is very small |

| Welding / Stitching Quality | Uneven seams, easy to miss weak points | Stable ultrasonic welding, uniform and reliable |

| Error & Rework Rate | Higher, because of fatigue and manual mistakes | Lower, with repeatable programs and clear process |

| Material Utilization | More waste due to inaccurate cutting | Optimized cutting path and web guiding reduces waste |

| Training Difficulty | Needs long-time training for skilled workers | Basic machine training, recipes can be saved and reused |

| Traceability | Hard to track who made which batch | Each batch can follow fixed parameters and production records |

| Operator Fatigue | High, long-time sitting/standing and repetitive actions | Lower, mainly monitoring and simple adjustments |

| Overall Cost (Long Term) | High labor cost, unstable output | Higher initial investment, but lower cost per gown over time |

Solution to problem during production

| Common Production Problems | Our Engineering Solutions |

|---|---|

| 1. Ultrasonic units fail after a few months (unstable frequency, overheating, low-quality horn/booster) | • Industrial-grade ultrasonic system (Branson-compatible) • Auto frequency tracking for stable energy output • Cooling optimization for long-time running • Pressure calibration scale to prevent misadjustment |

| 2. Gown size deviation ±1–2 cm (unstable tension, weak EPC, poor alignment) | • High-response EPC with servo correction • Constant-tension unwinding system • Mechanical structure designed for ±2 mm tolerance • Full alignment & verification before shipment (FAT report available) |

| 3. Too much manual operation slows production (patch / ties / feeding management) | • Automatic reinforcement patch feeding & positioning • Automatic band/tie handling options • Optimized feeding path to reduce manual loading and keep stable output (actual labor depends on your line configuration) |

| 4. Material drifting / off-track during running | • Balanced & hardened rollers for stable web guiding • Servo-based tension control system • High-sensitivity EPC sensor for thin SMS/SMMS • PLC auto-correction logic for drift compensation |

| 5. Cutting blade / die tool wears too fast | • Tungsten-carbide hardened cutting tools (long lifetime) • Pressure adjustment scale for correct contact force • Pre-shipment alignment verification • Lower consumables cost over long-term production |

| 6. Frequent machine stops due to sensor errors | • Panasonic / Omron sensor package • Standardized wiring with labeling & anti-interference design • Standard spare parts list provided • Remote troubleshooting support to reduce downtime |

| 7. After-sales support is slow or cannot solve root causes | • 7-hour response commitment • Online engineering support + video diagnostics • Remote PLC access for parameter tuning and alarm analysis • Clear SOP for operator & maintenance training |

| 8. Speed cannot reach promised output | • Pre-shipment speed test (video + FAT checklist) • Stable working speed based on gown design and material • Low-vibration structure design • SOP provided for speed optimization and stable running |

FAQ Surgical Gown Making Machine

What Is an Automatic Surgical Gown Making Machine?

An automatic surgical gown making machine produces disposable gowns from non-woven roll material through feeding, ultrasonic sealing, die cutting, folding, and stacking, controlled by PLC recipes.

It is suitable for SMS / SMMS / PP non-woven and reinforced critical-zone gown designs.

What Makes Gown Automation Stable?

A stable gown production line depends on three repeatable factors:

Tension control for size repeatability

Ultrasonic energy consistency for sealing strength

Accurate die-cut alignment for clean contours and easy sleeve joining

That is why we apply servo tension + EPC correction + auto-frequency tracking to reduce size deviation and welding defects.

What materials are commonly used to make surgical gowns?

Most surgical gowns are made from SMS or SMMS nonwoven fabric because they offer strong protection and good breathability. For higher protection levels (AAMI 3–4), many factories add reinforced PE film or microporous laminated material in critical zones.

How many workers do I need to run the machine?

A fully automatic surgical gown line typically needs only 1–2 operators. Their main tasks are loading materials, monitoring the machine, and collecting finished gowns. This greatly reduces labor costs compared to semi-automatic lines.

What is the production speed of the machine?

Most automatic gown machines run at 20–25 pieces per minute. Reinforced gowns may run slightly slower because they require more ultrasonic sealing or hot melt gluing steps.

What maintenance does the machine require?

Daily maintenance is simple and includes:

Cleaning the ultrasonic molds and horns

Checking alignment of sealing and cutting parts

Lubricating moving components

Replacing blades or worn parts when needed

A quick daily check plus a monthly preventive inspection keeps the line stable.

What utilities does the machine need?

The machine typically requires:

Electricity: 380V, 50/60Hz (customizable)

Air supply: 0.6–0.8 MPa

Ultrasonic sealing does not require heating elements, so no extra heating equipment is needed.

Can the machine produce different sizes?

Yes. The line can produce S, M, L, and XL sizes. Size changes are done by adjusting the cutting width, sleeve length, and strap positions. A normal size changeover takes 10–20 minutes.

WHY US

The Advantages You Get When Working With Us

Proven Technical Strength

We build our machines with stable structure, high-precision ultrasonic systems, and reliable PLC control. Every detail is designed to give consistent sealing quality and long-term performance.

Over a Decade of Industry Experience

We have years of experience in disposable medical product automation. This helps us understand real factory challenges and deliver solutions that work in daily production — not just on paper.

Fast and Professional Response

Customers never wait. Whether it’s technical support, quotation, or troubleshooting, our team replies quickly and clearly. We know speed matters in this industry.

Easy Maintenance

Our machines are built with accessible parts, clear structure, and simple daily checks. Operators can clean, adjust, or replace common parts quickly, keeping downtime to a minimum.

User-Friendly Operation

The machine is designed so new operators can learn it within a short time. Clear touch-screen menus, automatic adjustments, and stable running reduce skill requirements and labor dependency.

Continuous Technology Upgrades

We keep improving the machine design, ultrasonic systems, and process flow every year. Customers benefit from updated configurations and more efficient solutions.

Long-Term Service & Full Support

From installation to training to after-sales, we stay with you for the long run. Spare parts, technical guidance, remote support — everything is provided continuously to keep your production running.

Focused on What Customers Care About Most

We understand your priority: stable output, easy operation, fast delivery, and low production cost. Every machine and every service we provide is centered on helping you achieve these goals.

Send us an message

If you have any enquiry about quotation or cooperation, please feel free to email us at dehengmachinery@gmail.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.