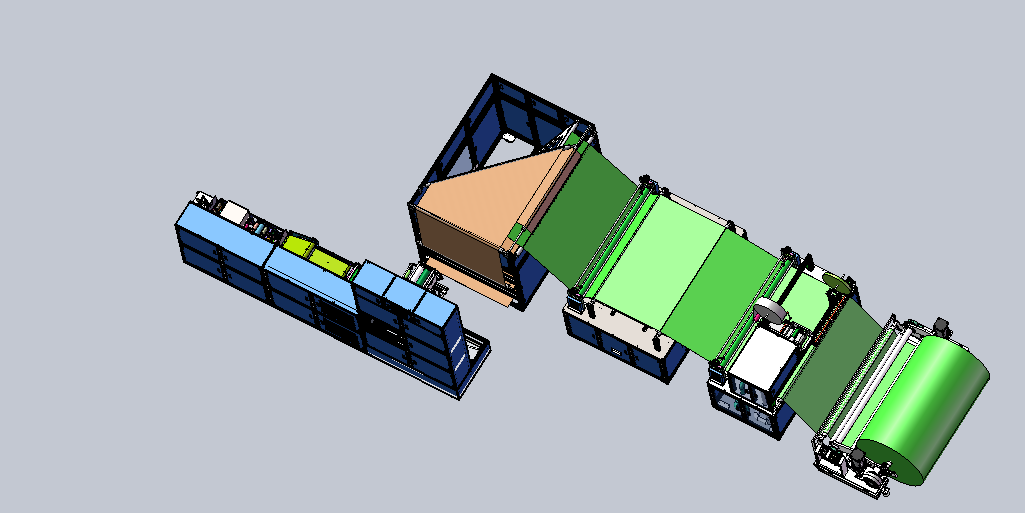

Disposable surgical drape making machine

The Medical Drape Making Machine is designed for producing a wide range of disposable surgical drapes and surgical packs used in hospitals, operating rooms, and sterile environments.

It supports various drape designs including:

Aperture drapes (hole drapes)

Fenestrated drapes

Ophthalmic drapes

Angiography drapes

U-drapes and full-body surgical sheets

This machine integrates automatic unwinding, folding, ultrasonic sealing, cutting, aperture forming, adhesive tape applying, and optional camera/labeling/PE film lamination depending on the model.

With high automation and stable performance, it helps medical consumable manufacturers increase production efficiency, ensure consistent quality, and reduce labor costs.

The machine is suitable for nonwoven fabric such as SMS, SMMS, PP, PE composite, and medical-grade laminate materials.

3.Samples:

Product size:

Unfold length 500-2000mm ,fabric roll width 450-1500mm

Fold length 150-250mm width 150-250mm

Machine characteristics

1.Machine Technical Data

2.Material Report

|

NO |

Material |

Diameter (mm) |

Tube Diameter |

Width (mm) |

Thickness |

Weight (Kg) |

|

1. |

non woven |

500-1000 |

Φ76.2 |

450-1500 |

20-60gsm |

50-80 |

3.Main machine structure description

| Material feeding unit |

1set |

| Center hole adhesive paster adding device |

1set |

| Punching device for hole |

1set |

| Folding device |

1set |

| Cutting device |

1set |

| Conveyor belt |

1set |

Customizable tooling and cutting molds allow production of:

Surgical hole drapes

Universal medical drapes

Split drapes

Ophthalmic drapes

Angio drapes

Ortho drapes

Large surgical sheets with reinforcement zones

Servo-driven cutter ensures accurate and clean hole forming.

Optional camera positioning for precise patch/hole alignment.

The machine can automatically apply:

Adhesive PE film

Isolation tape

Sticky reinforced patches

Absorbent reinforcement zones

Seals borders, reinforcement areas, folding edges, and connection lines.

No needle, no thread → no contamination.

Only 1–2 operators are needed.

Automatic stacking and counting available.

We can configure the machine based on your drape style:

Aperture size

Positioning

Film size

Tape width

Drape dimension

Folding method

Works with:

SMS

SMMS

Laminated sterile materials

PP+PE composite

Absorbent pads

PE film

Suitable for continuous 24/7 production.

Industrial PLC + servo motors for consistent performance.

| Item | Details |

|---|---|

| Model | DH-Drape |

| Applicable Materials | SMS, SMMS, SMMMS, Non-woven fabric, Laminated PE film, Reinforced absorbent materials |

| Finished Product Types | Standard surgical drapes, universal drapes, aperture drapes, reinforced surgical drapes |

| Material Width | 600–2000 mm or more size (customizable based on drape size) |

| Production Speed | 15–28 pcs/min (depending on drape type & reinforcement) |

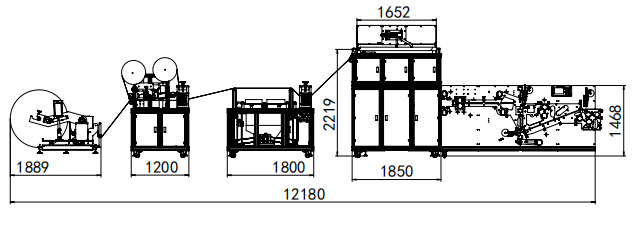

| Machine Size Range | 7–10 m (L) × 1.8–2.2 m (W) × 1.8 m (H) — varies by configuration |

| Machine Weight | 1500–2200 kg |

| Max Unwinding Diameter | 800–1200 mm |

| Fold Type Options | “Z” fold, “N” fold, Single fold, Multi-layer fold |

| Ultrasonic System | based on design |

| Punching Style | Cold knife / Hot knife / Ultrasonic punching (for aperture drapes) |

| Reinforcement Lamination | Optional PE film / absorbent layer / anti-fluid fabric |

| Edge Sealing Method | customized |

| Cutting Method | Servo-controlled rotary cutter or pneumatic cutter |

| Control System | PLC + Touch screen (Omron / Mitsubishi / Inovance optional) |

| Driving System | Servo motors for feeding, folding, welding & cutting |

| Power Supply | 380V, 3-phase, 50/60Hz (customizable to local standards) |

| Total Power Consumption | 8–12 kW (depends on modules) |

| Air Consumption | 0.6–0.8 MPa (500–800 L/min) |

| Operator Needed | 1 person |

| Production Mode | Fully automatic continuous running |

| Applications | Hospitals, surgery rooms, clinics, PPE factories, OEM drape production |

Our machine can produce:

Aperture/hole drapes

Fenestrated drapes

U-drapes

Universal sheets

Eye/ophthalmic drapes

Angio/ortho drapes

Customized OR drape designs

Yes. We support:

PE film with adhesive

Absorbent pad reinforcement

Nonwoven sticky patches

Custom-shaped isolation film

Please provide:

Drape size (length × width)

Aperture size & position

Film type & size

Tape type & width

Material GSM

Expected daily output

Voltage requirement

Sample photo or drawing

Depending on model and drape complexity, typically 10–25 pcs/min.

Only 1–2 operators for a full production line.

Yes, we support:

PP+PE

SMS laminate

PE protective film

Medical absorbent materials

Yes.

We provide:

Online video installation

Full operation manuals

Professional after-sales technical support

Optional onsite installation

Yes, send us your drape design, and we can produce samples for confirmation.