Our Automatic Bouffant Cap Making Machine is designed for producing nonwoven disposable caps widely used in hospitals, laboratories, food processing plants, cleanrooms, beauty salons and hygiene industries.

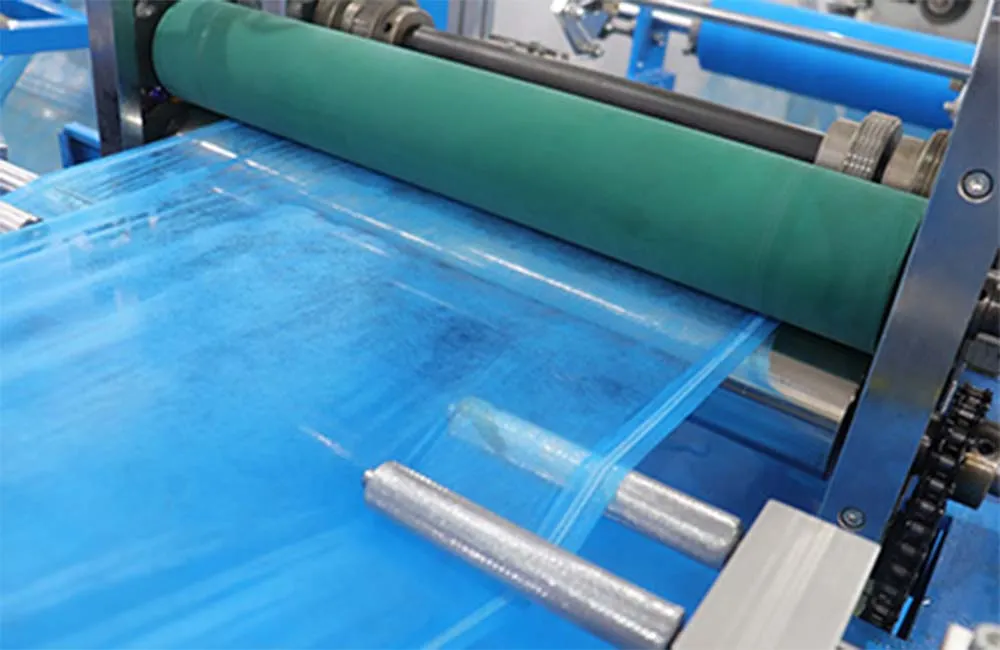

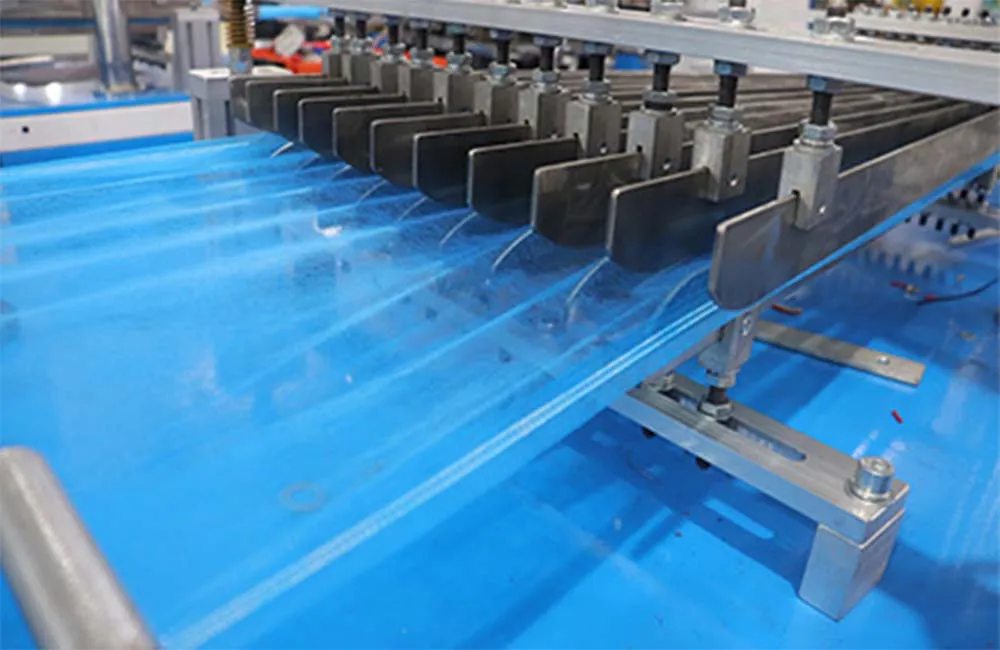

The machine integrates material feeding, folding, elastic inserting, ultrasonic sealing and cutting into one continuous production line. With stable performance and high output, it helps factories replace manual production and significantly reduce labor costs.

Compatible with PP nonwoven fabric, the machine offers adjustable cap sizes—typically from 18” to 24”—to serve different industries and market demands.

Fully Automatic Production

Material feeding, folding, sealing and elastic inserting are all completed in a single continuous process.

High-Precision Elastic Control

Ensures uniform tension and strong sealing for comfortable and durable caps.

Ultrasonic Bonding Technology

Clean, firm and eco-friendly sealing without glue or chemicals.

High Productivity

Running speed reaches 80–120 pcs/min depending on fabric quality and cap size.

PLC Touch Screen Control

Easy operation, real-time monitoring, and quick switching of production parameters.

Adjustable Cap Size

Supports multiple sizes (18–24 inches) for medical, food and household applications.

Stable Structure & Low Noise

Frame is welded and reinforced for long-term durability and quiet operation.

Low Labor Requirement

Only 1 operator is needed, making it ideal for high-volume production.

Main machine configuration:

| Item | Specification |

|---|---|

| Machine Name | Automatic Bouffant Cap Making Machine |

| Material | PP Nonwoven Fabric |

| Cap Size | 18–24 inches (Adjustable) |

| Production Speed | 80–120 pcs/min |

| Sealing Method | Ultrasonic sealing |

| Elastic Width | 4–6 mm (Customizable) |

| Control System | PLC + Touch Screen HMI |

| Power Supply | 220V/380V, 50–60Hz |

| Air Requirement | 0.5–0.6 MPa |

| Machine Weight | Approx. 1000–1300 kg |

| Machine Dimensions | 3800 × 900 × 1400 mm |

| Item | Specification |

|---|---|

| Machine Name | Automatic Bouffant Cap Making Machine |

| Material | PP Nonwoven Fabric |

| Cap Size | 18–24 inches (Adjustable) |

| Production Speed | 80–120 pcs/min |

| Sealing Method | Ultrasonic sealing |

| Elastic Width | 4–6 mm (Customizable) |

| Control System | PLC + Touch Screen HMI |

| Power Supply | 220V/380V, 50–60Hz |

| Air Requirement | 0.5–0.6 MPa |

| Machine Weight | Approx. 1000–1300 kg |

| Machine Dimensions | 3800 × 900 × 1400 mm |

The machine mainly works with PP nonwoven fabric, typically between 9–20 gsm. Other lightweight nonwoven materials may also be compatible depending on customer requirements.

Also work for plastic PE film.

The standard production speed is 120-200 pieces per minute, depending on fabric quality, elastic tension, and desired cap size.

Yes. The standard machine supports 18–24 inch cap sizes. The size change mainly involves adjusting the folding structure and elastic length. More size pls contact me for detail: 0086-18066372911.

Yes. We provide online installation guidance, video instructions, and real-time technical support.

If required, we can also arrange engineer onsite service (customer covers travel cost).

The machine comes with a 1-year warranty for all core components, including:

Ultrasonic system

Electrical parts

Motors and sensors

PLC & HMI

Lifetime technical support is free.

We offer multiple support channels:

24–48 hour online troubleshooting

Remote video diagnosis (WhatsApp / WeChat / Zoom)

Parameter correction and guidance

Free training on operation and maintenance

For urgent issues, we can send replacement parts immediately.

Common spare parts such as: ultrasonic horns, blades, rubber rollers, sensors, belts, etc.

are always kept in stock.

We ship within 24 hours by DHL/FedEx.

Customized parts normally take 3–7 days.

Yes. We support customization of:

Cap size (18–24 inch)

Elastic width & tension

Feeding structure

Folding style

Machine speed

Frame size

We also provide upgrade services for old machines (ultrasonic replacement, tension system stabilization, elastic feeding upgrades, etc.).