The Doctor Cap Making Machine is a fully automatic production line designed for manufacturing disposable doctor caps / surgical caps used in hospitals, laboratories, cleanrooms, and food-processing environments.

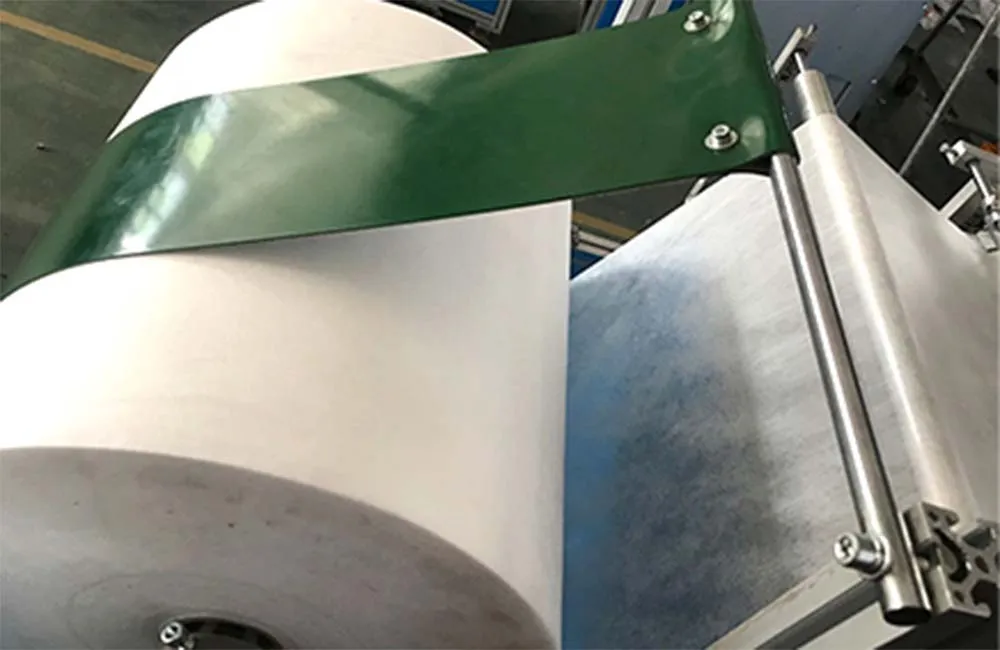

Using non-woven fabric (PP / SMS) as raw material, the machine completes automatic feeding, folding, forming, elastic welding, cutting, and finished product output in one continuous process.

Equipped with advanced ultrasonic welding technology, the caps are sealed firmly without glue, ensuring clean, hygienic, and stable quality.

The machine can produce different cap sizes and styles by changing molds, making it ideal for factories requiring flexible, high-capacity production.

Fully Automatic Production

One machine completes feeding, forming, ultrasonic welding, elastic attaching, cutting, and output. Requires only 1 operator.

High Production Speed

Adjustable speed from 70–180 pcs/min, depending on cap size and material.

Ultrasonic Welding System

Clean, strong, and stable sealing; no glue, no high temperature, suitable for medical-grade products.

Compatible with Multiple Materials

Works with PP, SMS, and various non-woven fabrics between 20–50 GSM.

Stable PLC Control System

Equipped with intelligent PLC + touch screen + automatic alarm and stop functions for safety and accuracy.

Automatic Material Detection

Machine stops automatically when raw material is finished to prevent waste.

Size & Mold Customization

Molds can be customized for different cap diameters, elastic styles, and country-specific designs.

Durable Structure

Aluminum alloy frame, anti-rust, long lifetime, suitable for 24/7 factory operation.

|

model |

DH-YSM |

|

Package size |

8520×880×1600mm(L*W*H) |

|

Capacity |

70-120PCS/MIN |

|

voltage |

220v/380v 60HZ |

|

Power |

11.6KW |

|

Weight |

1800KG |

|

Product size |

3200*1200MM(L*Depth) |

It produces disposable doctor caps / surgical caps with elastic or with tie, suitable for hospitals, clinics, cleanrooms, labs, and food processing plants.

Standard running speed is 70–180 pcs/min, depending on size and elastic settings.

Only 1 person is needed to operate the entire machine.

We will send professional technician to your company to install the machine and train your staff until they could operate the machine independently.

Yes. We can customize molds to match your sample size, country standard, or elastic/tie-on version.