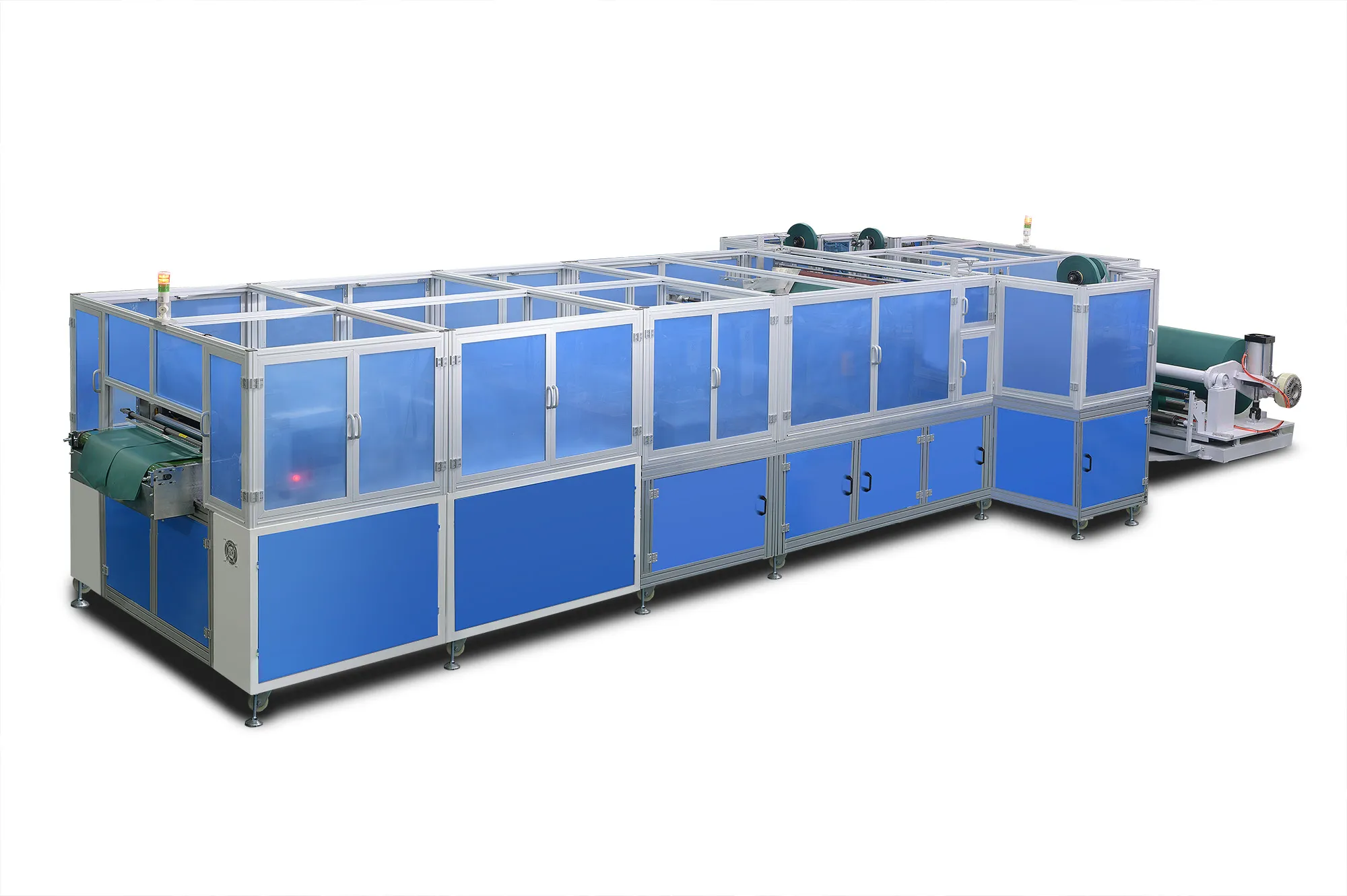

Our Fully Automatic Surgical Gown Body Making Machine is designed for high-efficiency production of the main body panel of disposable surgical gowns. It is the first and most essential part of a complete surgical gown production line.

When combined with a Surgical Gown Sleeve Making Machine and Cuff Attaching Unit, you can produce finished AAMI Level 2–4 surgical gowns with stable quality and high productivity.

This machine integrates:

Automatic unwinding

Precision folding

Ultrasonic sealing

Servo cutting

Automatic stacking

It allows manufacturers to achieve stable, large-scale gown production with reduced labor and improved quality consistency.

Applications:

Hospitals · OEM manufacturers · Disposable PPE suppliers · Medical textile factories

Stable output from 20–25 pcs/min (adjust based on your actual speed).

Suitable for factories targeting high-volume medical orders.

Servo-controlled folding keeps both sides symmetrical, reducing fabric waste and defect rate.

Reinforced bonding on shoulder and side seams.

Supports AAMI Level 2, 3, and 4 surgical gown standards.

Works with:

SMS

SMMS

Spunbond PP

PP + PE composite

Custom GSM (30gsm–45gsm)

Only 1–2 operators required.

Replaces traditional manual sewing teams of 6–10 workers.

Modular structure and tool-less adjustment → faster switchover for different gown types.

Reinforced frame, industrial PLC, and servo system ensure 24/7 continuous operation.

Feeding → Cutting → Folding → Ultrasonic Sealing → Shaping

Stronger seams, lower noise, and less downtime.

AAMI Level 2/3/4 compliant.

Can connect sleeve machine + reinforcement machine + folding/packing system.

One operator can monitor multiple lines.

Sealing structure designed to avoid tearing during surgical procedures.

Online guidance, spare parts package, English documentation, and remote debugging.

Velcro / Hook & Loop

Tie Strap

1 Tie (basic gown)

2 Ties (standard gown)

4 -6 Ties (premium surgical gown)

Set-in Sleeve (most common)

Raglan Sleeve

Knitted Cuff

Elastic Cuff

Chest reinforcement patch

Full body reinforcement panel

Sponge strip reinforcement

No reinforcement

M / L / XL / XXL (custom available)

(Size determines mold + folding structure)

SMS

SMMS

PP + PE Laminated Fabric

Weight: 30gsm / 35gsm / 40gsm / 45gsm

Blue

Green

White

Custom hospital color

To receive an accurate machine quote, please share:

M / L / XL / XXL or your custom drawing.

Neck: Velcro or tie?

Waist ties: quantity & length

Sleeve type

Cuff type

Patch size, location, or sample photo.

Fabric type + GSM.

Daily or monthly output.

380V / 220V / 50Hz / 60Hz.

Bulk packing or customized folding.

Surgical gown main body shaping

Disposable medical gown manufacturing

Isolation gown (body panel)

Hospital protective wear

Nonwoven PPE production lines

For more detail and case study:

|

Model |

DH-G |

|

Speed |

10-15pcs/min |

|

Voltage |

220V or 380V |

|

Power |

7kw |

|

Net weight |

2300kg |

|

Machine dimension |

8000*2100*2500mm (L*W*H) |

Compatible with SMS, SMMS, Spunbond PP, and other nonwoven materials used for hospital gowns.

Usually 1–2 operators are enough because the machine is fully automatic.

Yes. We can customize the folding width, sealing mold, cutting knives, and layout based on your required gown size.

Yes. We offer on-site installation or online guidance.

Engineers can train your operators until they fully understand the operation.

Typically one-year warranty, with lifelong technical support.

Yes. This machine produces the main body.

For a complete gown, you need:

Sleeve making machine

Cuff attachment

Patch/reinforcement machine (optional)

Gown folding & packaging machine (optional)

1. Complete production solution, not just one machine

We design the full surgical gown line for you, including workflow, labor planning, and space layout.

2. Experience with US, Mexico, Turkey, and Middle East buyers

We understand different hospital standards and packaging requirements.

3. Reduced production cost & higher efficiency

Better than manual sewing, faster delivery for your buyers.

4. Reliable technical support

Most questions solved within 30 minutes via video.

5. Long-term spare parts supply

No need to worry about downtime.