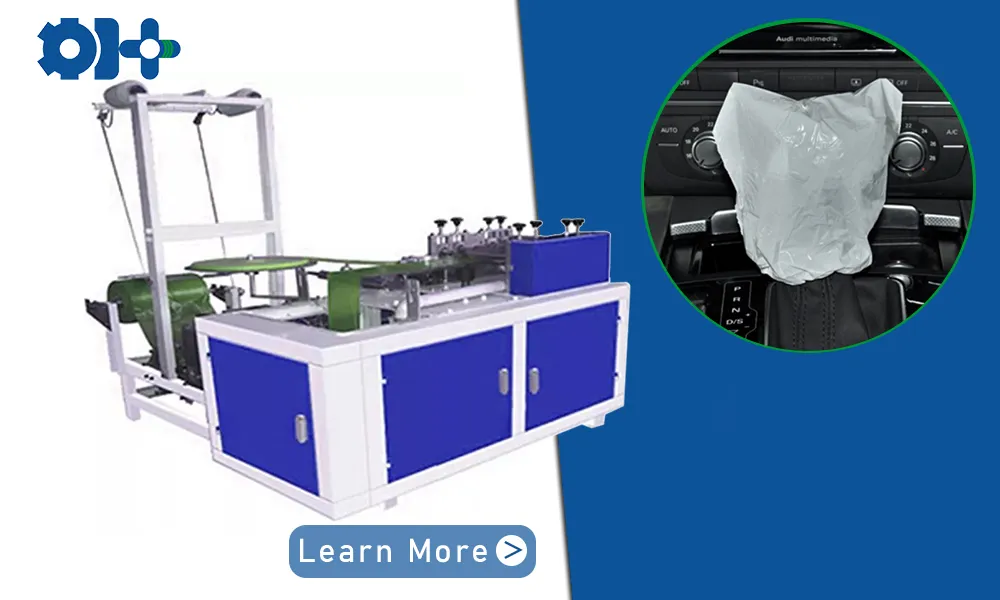

The Plastic Car Handle Cover Making Machine is designed for high-speed, continuous production of disposable automotive protective covers. It supports PE film , ensuring strong sealing and stable quality for car door handle protection during vehicle maintenance, painting, detailing, and delivery.

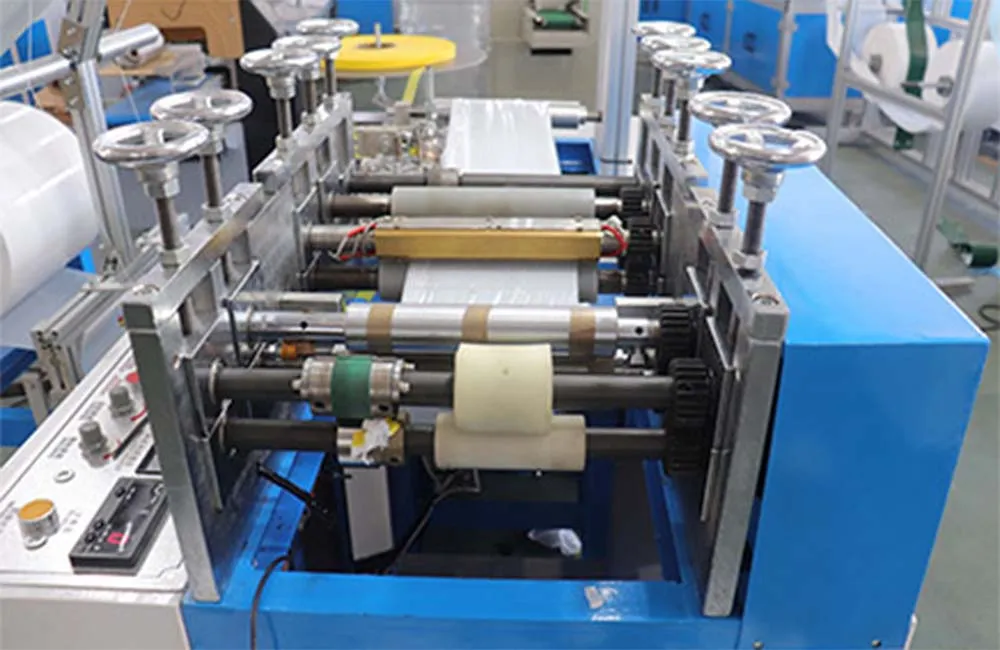

This machine integrates automatic feeding, ultrasonic sealing, folding, cutting, and counting into one compact line. With quick mold change, it can make different sizes of handle covers and other small protective covers used in auto workshops.

Ideal for manufacturers supplying car detailing centers, auto repair shops, paint booths, and vehicle delivery departments.

✔ Suitable for PE

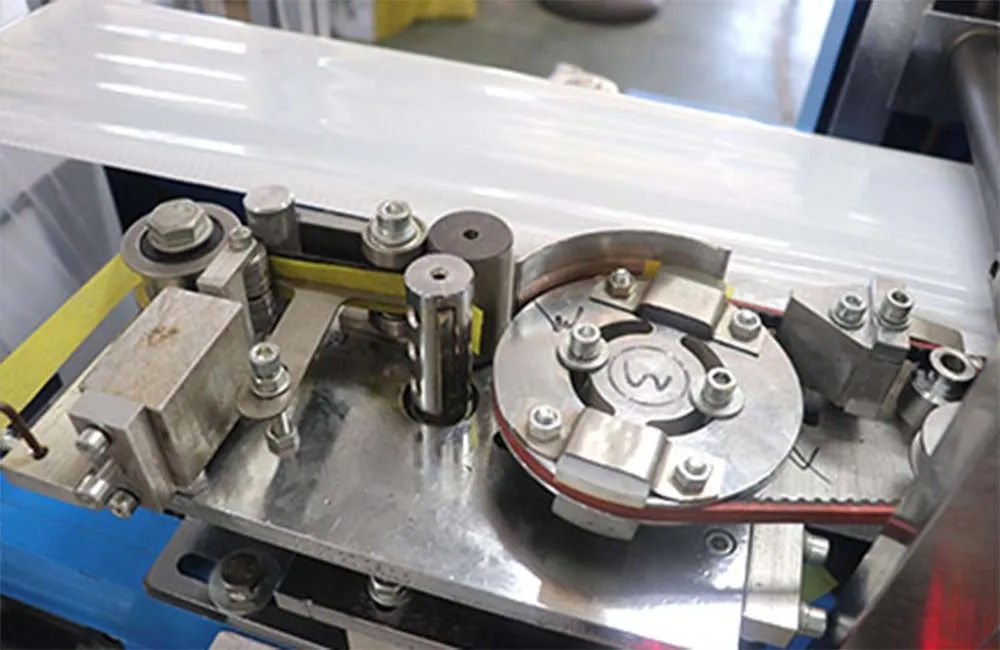

✔ High-speed ultrasonic sealing for clean and firm welding

✔ Multi-size production (quick mold change)

✔ Fully automatic operation: feeding → sealing → folding → cutting → counting

✔ Stable performance for 24/7 production

✔ Low material waste and easy size adjustment

✔ Can produce other covers: gear shift covers, steering wheel wrap covers, maintenance dust covers

Yes. Besides car handle covers, it can also produce:

Gear shift covers

Steering wheel sleeves

Dust prevention sleeves

Small instrument covers

Packaging protective covers

|

Model |

PE、CPE |

|

Machine size |

1500mm*1500mm*1700mm (L*W*H) |

|

Package size |

1700mm*1550mm*1800mm(L*W*H) |

|

Capacity |

150-180 Pcs/min |

|

voltage |

220v/380v(according to customer requirement) |

|

Weight |

550kg |

|

power |

3.5kw |

|

Use material |

Rubber band,plastic film |

We provide:

1-year warranty for major parts

Online support within 7 hours

Video training & operation guide

Engineers available for overseas debugging (optional)

Spare parts package included with each machine