Machine Introduction

This case study introduces our fully automatic cut & fold machine developed for medical-grade hand towels (non-dispenser use), widely used in hospitals, clinics, and surgical scrub rooms.

Unlike standard tissue converting machines designed for dispenser formats, medical hand towels require more consistent folding geometry, controlled handling, and repeatable final dimensions to support hygiene workflows and downstream packaging.

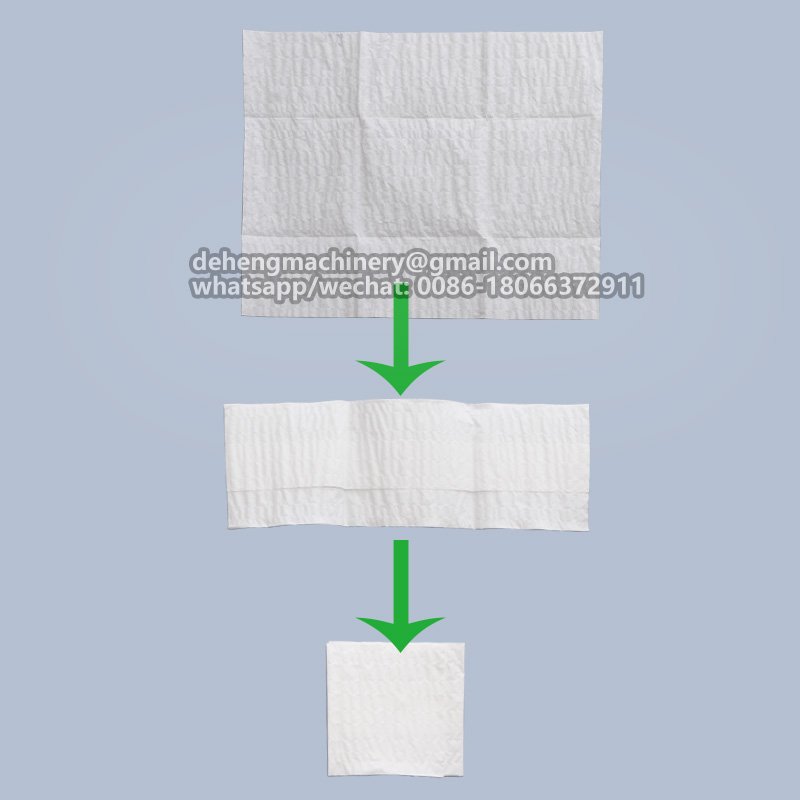

The process is engineered as:

Vertical folding (C-fold or W-fold) → cutting → final folding by required towel size, ensuring stable shape and stack alignment across different specifications.

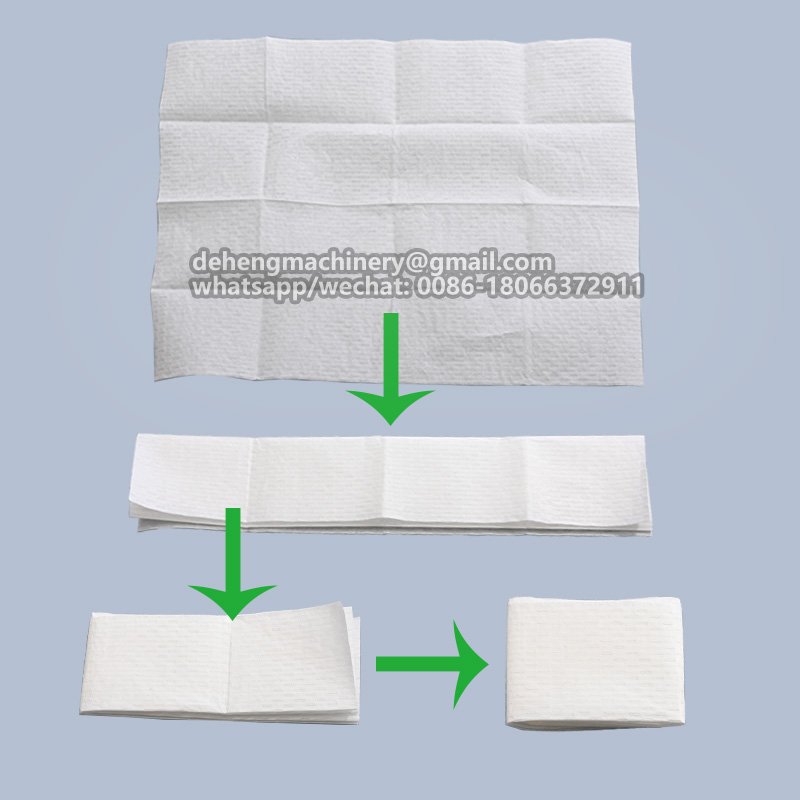

Supported formats: C-fold & W-fold (Vertical fold options)

Final size folding: customizable by towel dimensions

Result: consistent output, reduced labor dependency, and medical-ready folding quality.

Designed for medical hand towels used in scrub rooms and hygiene-controlled environments — not for dispenser tissue production.

C folding

M folding

Case Study | Fully Automatic Scrim Paper Hand Towel Cut & Fold Solution

| Section | Content |

|---|---|

| Industrial Background | Scrim paper hand towels are widely used in hospitals, clinics, and surgical scrub rooms for hand drying after surgical hand washing. Demand is stable and specification requirements vary by market, hospital system, and end user. |

| Main Market Issues | • Most production lines rely on semi-automatic cutting or long-blade cutting systems • Folding design is fixed and cannot support multiple fold types on one machine • Finished towel size adjustment is limited and inflexible • Changeover requires mechanical modification or separate machines • Production speed is constrained by cutting and folding limitations |

| Customer Demand | • Flexible folding formats (e.g. C-fold, W-fold) on the same machine • Adjustable towel size to meet different market standards • Stable folding quality across different configurations • Higher and more consistent production speed • Reduced reliance on manual operation |

| Solution | A fully automatic scrim paper hand towel cut-and-fold machine designed specifically around the structural behavior of scrim material. Cutting and folding are integrated into one continuous process, enabling flexible folding patterns and size adjustment without manual intervention. |

| Applications | • Medical scrim paper hand towels• Surgical scrub room drying towels• Disposable hospital hygiene consumables |

Interested in this solution? Talk to us for technical details.

Vertical Fold Options (Before Final Size Folding)

C-Fold (Vertical fold)

W-Fold (Vertical fold)

Final Folding by Required Towel Size

After vertical folding, towels are folded again based on customer-required dimensions, forming the final stack size ready for packing.

Working Process

Material Feeding

Scrim reinforced paper rolls are loaded onto the unwinding station(s) with stable feeding control.Tension Control & Web Guiding

The web passes through tension and guiding systems to ensure smooth, wrinkle-free feeding and stable fold alignment.Vertical Folding (C-fold / W-fold option)

The material is folded longitudinally to form the internal structure — C-fold or W-fold.Cutting to Length

The vertically folded web is cut into individual towel lengths. Length parameters are adjustable.Final Folding by Required Towel Size

After cutting, each piece is folded again based on the final customer-required towel dimensions, forming a consistent stack format.Discharge & Stacking

Finished towels are discharged in a well-aligned, pack-ready format suitable for manual or automated packaging.

Main configuration

| Machine speed | 350-450 pcs/min |

| Product size | Customized, up to 60*60cm. |

| Power | 21kw |

| Dimension | 9400*3600*1720 mm |

| Voltage | 380v, 60hz, 3ph 4line |

| Air | 0.6-0.8 mpa |

| Weight | 2600kg |

Not a dispenser tissue machine. Built for medical hand towel requirements.

Medical hand towels demand repeatable folding geometry, stable final size, and pack-ready consistency for hygiene-controlled environments and standardized hospital workflows.

Key Features & Benefits

| Feature | Benefit |

|---|---|

| Dual unwinding stations | Produce C-fold and W-fold simultaneously |

| Adjustable towel length | Match different market requirements |

| Integrated cutting & folding | Continuous, high-speed production |

| Pneumatic loading & tension control | Reduce labor and prevent paper damage |

| Flexible size & fold adjustment | No mechanical modifications needed |

WHY US – Professional Manufacturer of Automatic Scrim Paper Towel Cutting And Folding Machines

Why Medical Disposable Manufacturers Choose Us

Industrial-Grade Engineering for Scrim Paper Towel Production

We design and manufacture fully automatic scrim paper hand towel cutting and folding machines with a stable mechanical structure, precise control systems, and proven automation logic. Built for continuous medical-grade production, not light-duty operation.

10+ Years Focused on Medical Disposable Automation

With over a decade of experience in medical disposable machine manufacturing, we understand real factory challenges: labor cost, folding consistency, hygiene standards, and production efficiency. Our machines are engineered for daily mass production, not theoretical output.

Fast Technical Response from the Machine Manufacturer

As a direct scrim paper towel machine manufacturer, we provide fast and accurate responses on machine configuration, customization, pricing, and technical support. No middle layers. No delays.

Low-Maintenance Automatic Folding Machine Design

Our automatic cutting and folding machines are designed with accessible components and clear layouts. Daily maintenance, cleaning, and adjustments are simple—helping factories reduce downtime and long-term operating costs.

User-Friendly Operation for Medical Towel Production Lines

The control system is designed for fast operator training. Touch-screen operation, automatic parameter control, and stable running reduce skill requirements and labor dependency in medical towel production lines.

Continuous Upgrades in PPE Machine Technology

We continuously improve PPE production machines, folding systems, and process flow. Customers benefit from updated configurations, higher efficiency, and future-ready solutions as market requirements evolve.

Full-Service Support for Scrim Hand Towel Machines

From installation and operator training to spare parts supply and remote technical support, we provide long-term service to ensure stable operation throughout the machine’s lifecycle.

Focused on Production Efficiency and Cost Control

Our priority is clear: stable output, flexible folding, easy operation, and controlled production cost. Every scrim paper towel machine and every service decision is built around these manufacturing goals.

Send us an message

If you have any enquiry about quotation or cooperation, please feel free to email us at dehengmachinery@gmail.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.