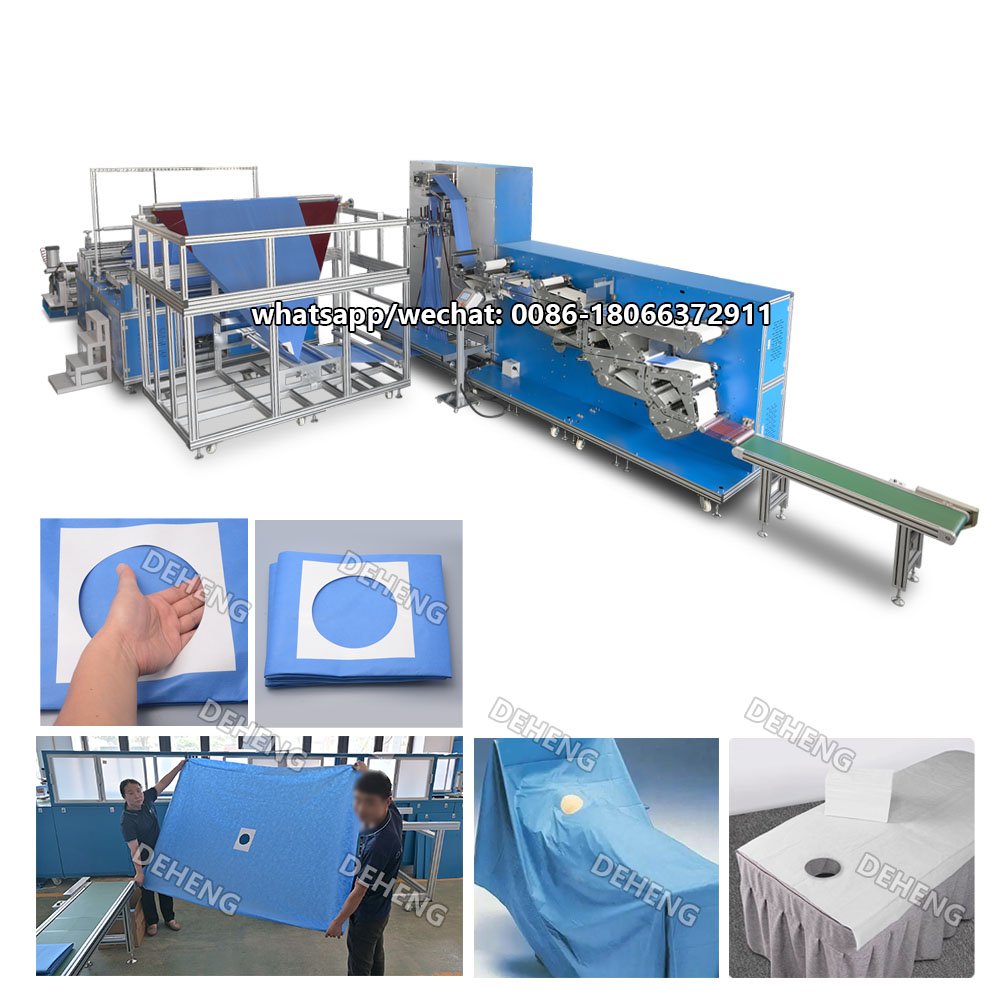

Fully Automatic Surgical Drape Making Machine (Hole Punch + Taping + Folding)

A complete production solution for disposable surgical drapes with reinforcement attaching, fenestration hole punching, adhesive tape application, cutting, folding, and stacking.

Production speed: 20–60 pcs/min (depending on drape design, hole pattern, and reinforcement requirements)

Operation required: 1–2 operators

Folding styles: Book fold / Zig-zag fold / Cross fold

Result: stable quality for export QC and pack-ready consistency for surgical kits

Surgical Drape Machine Project Report

| Item | Details |

|---|---|

| Industry | Medical PPE Manufacturing (Disposable Surgical Drapes) |

| Location | Morocco |

| Products Made | Surgical Drapes, Reinforced Drapes |

| Previous Production Method | Manual folding + simple semi-automatic machines |

| Main Challenges Before Automation | Uneven folding, unstable punching quality, high manual handling, low productivity, labour intensive |

| Reason for Upgrading | Needed stable folding & punching accuracy for export standards and to reduce labour cost & variation |

Problem → Solution → Result

| Stage | Description |

|---|---|

| Problem | • Manual folding caused uneven drape size and unstable quality • Hole punching produced uneven / shallow holes, especially on reinforced areas • Labour-intensive — required 5–6 people to maintain output • Output limited (approx. 2,000–2,500 drapes/day, design dependent) • Quality inconsistent and failed some export QC checks |

| Solution | • Installed Deheng Fully Automatic Surgical Drape Making Machine to replace manual folding • Added servo-controlled folding unit for uniform width and stable size • Upgraded punching module with high-hardness tooling for long life and stable punching depth • Integrated EPC & tension control to stabilize fabric feeding • Enabled remote PLC support for faster debugging and parameter setting |

| Result | • Output increased to 10,000–11,000 drapes/day (depending on drape size and design complexity) • Labour reduced from 5–6 operators → 2 operators (feeding + packing) • Folding became more consistent, size variation reduced to ±2 mm • Machine supported continuous 24/7 operation with stable performance • Finished drapes passed export inspection more easily |

Get a Drape Solution Proposal

Send us your drape requirements:

drape size (L × W)

hole type (round / square / oval / U-shape / multi-hole)

reinforcement style (SMS/SMMS/PE film/absorbent pad)

tape option (frame tape / full tape / partial tape / glue)

folding style (book / zig-zag / cross)

packing method (stack / sterilization pouch / kit packing)

We will recommend the best configuration and quotation.

What is surgical Drape making machine

A surgical drape making machine automatically produces disposable drapes from SMS/SMMS/laminated materials, integrating reinforcement attaching, hole punching, taping, cutting, folding, and stacking in one PLC-controlled line.

It supports custom sizes and hole patterns, with repeatable output for export QC and surgical kit packing.

Working Process — Full Medical Drape Production Line

Medical drapes are made through multiple automatic modules:

Drape Forming Section – feeds non-woven/laminated roll material and performs basic shaping.

Reinforcement & Lamination Section – applies PE film, SMS reinforcement, or absorbent layers.

Hole Punch & Taping Section – performs fenestration hole cutting and applies adhesive tape.

Folding Section – book fold, zig-zag fold, or customized folding requirements.

Final Cutting & Stacking – cuts drape into final dimensions and automatically stacks.

This integrated process ensures stable quality, accurate hole punching, and fast production with minimal labor.

Modules Overview (Key Functions)

| Module | What It Does |

|---|---|

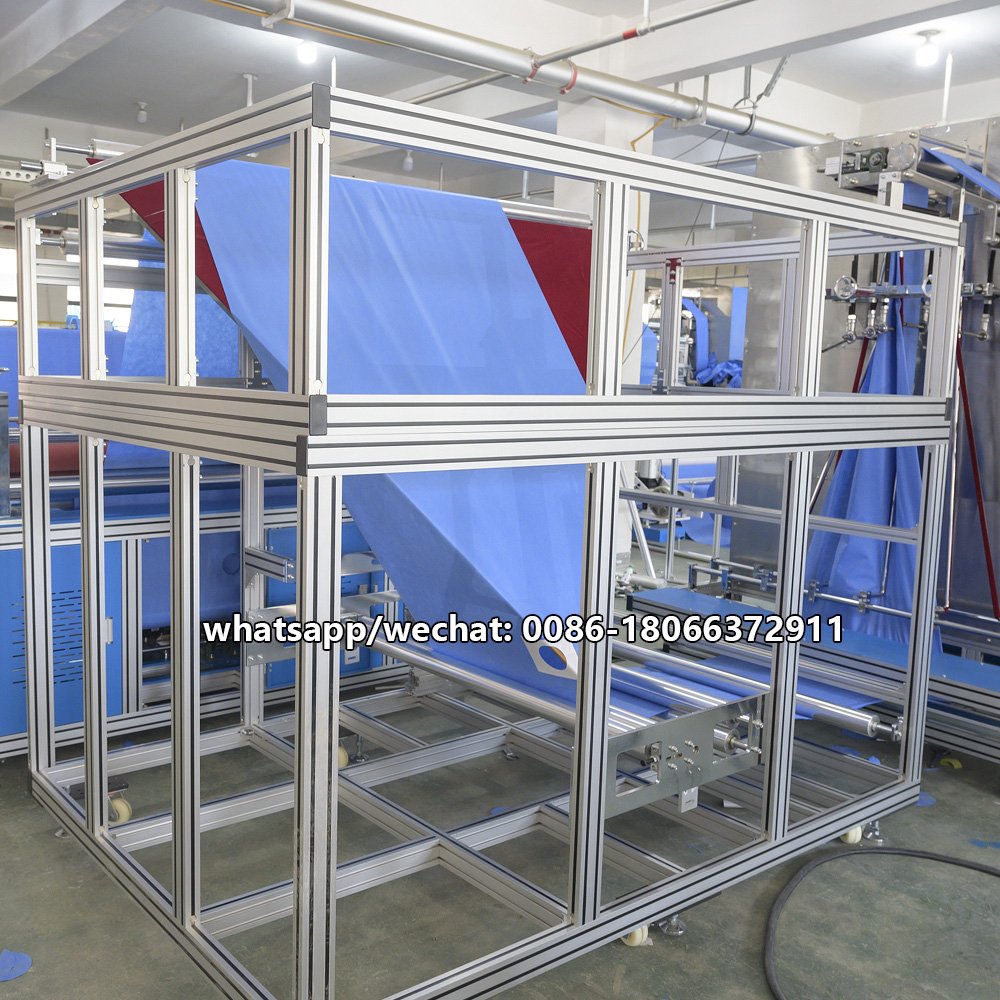

| EPC Edge Alignment | Prevents web drifting and keeps material centered |

| Servo Tension Control | Stabilizes feeding for consistent size and hole position |

| Reinforcement Patch Placement (Optional) | Automatically positions reinforcement material accurately |

| Ultrasonic / Hot Melt Bonding (Optional) | Secures reinforcement layers with stable sealing strength |

| Fenestration Hole Punching | Custom shapes: round / oval / square / strip / multi-hole |

| Waste Collection | Keeps machine clean during continuous production |

| Tape / Glue Application (Optional) | Frame tape, full tape, partial tape, or medical glue sealing |

| Folding Modules | Book fold / zig-zag fold / cross fold (customizable) |

| Auto Stacking | Pack-ready output for sterilization or kit packing |

Application

All Surgical Drape Types This Machine Can Produce

Common Surgical Drape Types Supported

Universal Surgical Drape

Ophthalmic Drape

ENT Drape

Urology / TUR Drape

C-section Drape

Gynecology Drape

Angiography / Cath Lab Drape

Orthopedic Drape

Laparoscopy Drape

Dental Drape

Other customized drapes available upon request

Customized Drape Designs — Made According to Your Requirements

Besides standard models, our machine supports fully customized medical drape designs, including:

✔ Custom hole/punch shapes

✔ Special tape layout or adhesive pattern

✔ Glue sealing or double tape reinforcement

✔ Extra reinforcement pads or multilayer lamination

✔ Size customization (small, medium, XXL drape, or oversized OT drape)

✔ Multiple folding sequences for OEM sterile package suppliers

✔ Extra die-cutting modules for complex shapes

✔ Any special surgical department requirements

We provide design support, CAD layout optimization, die-cut tooling design, and complete machine customization based on your drape specification.

Main Configuration

| Item | Specification |

|---|---|

| Machine Type | Fully Automatic Surgical Drape Making Machine |

| Production Speed | 20–60 pcs/min (depending on design & reinforcement) |

| Applicable Material | SMS / SMMS / Spunbond / Reinforced PE Film (optional) |

| Drape Types | Standard Surgical Drape, Reinforced Surgical Drape |

| Sizes Supported | Adjustable / customizable |

| Ultrasonic System | High-frequency ultrasonic sealing, automatic frequency tracking |

| Cutting Method | Precision rotary blade |

| Control System | PLC + Touch Screen (English interface) |

| Power Supply | 380V, 50/60Hz (customizable) |

| Air Pressure | 0.6–0.8 MPa |

| Installed Power | 12–18 kW (varies by model) |

| Machine Dimensions | Approx. 11 m (L) × 3–4 m (W) |

| Operation Required | 1–2 operators |

| Changeover Time | 10–20 minutes (depending on tooling and tape layout) |

| Features | reinforcement patch, taping, gluing, hole punching, folding, stacking, customization |

| After-Sales Service | Remote support, spare parts, installation guidance |

Main Feature

PLC Intelligent Control System

The machine is equipped with a high-precision PLC intelligent controller to manage each production step, including fabric feeding, reinforcement welding, lamination, hole punching, taping, folding, and stacking.

Customized & Flexible Drape Production

Choose different modules based on your drape design:

Hole punch shapes: round / square / oval / multi-hole / strip

Taping styles: frame tape / full tape / partial tape / glue

Reinforcement materials: SMS/SMMS / PE film / absorbent pad

Folding styles: book fold / zig-zag / cross fold

Modules can be added or removed based on project requirements for better investment control.

Non-Stop Continuous Running

Engineered for large-volume medical drape production, the machine uses:

Servo-driven tension control

Precise EPC edge alignment

High-hardness die-cutting tools

Heavy-duty ultrasonic welding

Smooth feeding and stable pulling system

These features ensure continuous, high-speed operation with clean punching, accurate taping, and consistent reinforcement welding — even in 24/7 production environments.

Remote Monitoring & Service System

With the integrated remote support controller, our engineers can:

Access machine settings

Diagnose alarms and errors

Adjust process parameters

Update software

Guide operators during production

This reduces downtime, speeds up troubleshooting, and keeps your line running at optimal performance.

Economic & Easy-Upgrade Modular Design

The machine is built with a modular structure, allowing customers to expand functions easily:

Add customized hole-punch modules

Add extra tape or glue stations

Add additional reinforcement pads

Add lamination unit

Upgrade folding modules

Expand production width or drape size

This gives factories better control over investment and lowers maintenance and operating cost.

Solution to problem during production

| Common Production Problem | Our Solution |

|---|---|

| Hole punching misalignment / unstable edges | Servo-synchronized punching + high-sensitivity EPC web guiding keeps hole position stable and edges clean |

| Taping position deviation / weak adhesion | Constant-tension tape unwinding + fixed pressure control ensures repeatable tape placement |

| Reinforcement patch misalignment | Automatic patch positioning + stable bonding (ultrasonic / optional hot melt) reduces shifting at high speed |

| Finished drape size inconsistency | Servo cutting + constant tension control delivers repeatable final dimensions |

| Folding not uniform / manual folding too slow | Automatic folding modules (book / zig-zag / cross fold) ensure consistent pack-ready folding |

| Changeover takes too long | Modular tooling + recipe settings enable faster switching between drape designs and hole patterns |

Need your drape drawing reviewed? Send us your drape size + hole layout + reinforcement + folding method — we can propose the best configuration.

FAQ Surgical Drape Making Machine

What materials are used to produce surgical drapes?

Surgical drapes are commonly made from SMS / SMMS nonwoven fabric, PE film, and laminated absorbent materials.

For reinforced drapes, factories often add absorbent pads or PE reinforcement layers to improve fluid control and barrier protection.

disposable surgical drape making machine

How many workers are needed to operate the drape machine?

A fully automatic drape line requires only 1–2 operators.

They mainly handle:

-

Loading the nonwoven/PE rolls

-

Monitoring hole punching, reinforcement, folding and taping

-

Collecting finished drapes

This greatly reduces labor cost and improves production stability.

What utilities does the drape machine need?

The machine typically requires:

-

Electricity: 380V, 50/60Hz (customizable)

-

Air supply: 0.6–0.8 MPa

-

No heating system is required because all sealing is done by ultrasonic or pressure bonding.

Do you provide installation and after-sales support?

Yes. We offer:

-

On-site installation and training

-

Remote video support

-

7-hour response service

-

Complete spare parts list

-

Online troubleshooting with PLC remote access

This ensures smooth operation after the machine is delivered.

Can the machine make different drape types and hole designs?

Yes. The machine supports:

-

Round, rectangle, square, and U-shape fenestration holes

-

Single or multiple holes in different positions

-

Reinforced drapes with absorbent or PE film

-

Z-fold, C-fold, or W-fold depending on customer requirements

Recipe settings allow quick changeover between different drape designs.

Does the machine include automatic folding and reinforcement placement?

Yes. The line includes:

-

Automatic reinforcement placement (PE film / absorbent pads)

-

Automatic tape application

-

Automatic folding system for consistent folding shape

-

Servo-controlled die cutting for accurate hole punching

These modules ensure high consistency and reduce manual handling.

How long does a size or design changeover take?

Most size or layout changes take 10–15 minutes, depending on whether the customer needs:

-

Hole size change

-

Folding pattern change

-

Reinforcement size adjustment

Quick-change die-cut tooling helps minimize downtime.

What maintenance is required?

Daily maintenance includes:

-

Cleaning ultrasonic horns and cutting blades

-

Checking alignment of die-cut and folding modules

-

Inspecting tape feeding and tension control

-

Lubricating moving parts as recommended

A short daily check plus monthly preventive maintenance keeps the machine stable.

WHY US

The Advantages You Get When Working With Us

Proven Technical Strength

We build our machines with stable structure, high-precision ultrasonic systems, and reliable PLC control. Every detail is designed to give consistent sealing quality and long-term performance.

Over a Decade of Industry Experience

We have years of experience in disposable medical product automation. This helps us understand real factory challenges and deliver solutions that work in daily production — not just on paper.

Fast and Professional Response

Customers never wait. Whether it’s technical support, quotation, or troubleshooting, our team replies quickly and clearly. We know speed matters in this industry.

Easy Maintenance

Our machines are built with accessible parts, clear structure, and simple daily checks. Operators can clean, adjust, or replace common parts quickly, keeping downtime to a minimum.

User-Friendly Operation

The machine is designed so new operators can learn it within a short time. Clear touch-screen menus, automatic adjustments, and stable running reduce skill requirements and labor dependency.

Continuous Technology Upgrades

We keep improving the machine design, ultrasonic systems, and process flow every year. Customers benefit from updated configurations and more efficient solutions.

Long-Term Service & Full Support

From installation to training to after-sales, we stay with you for the long run. Spare parts, technical guidance, remote support — everything is provided continuously to keep your production running.

Focused on What Customers Care About Most

We understand your priority: stable output, easy operation, fast delivery, and low production cost. Every machine and every service we provide is centered on helping you achieve these goals.

Send us an message

If you have any enquiry about quotation or cooperation, please feel free to email us at dehengmachinery@gmail.com or use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.